Notice: Uninitialized string offset: 19 in /home/d0dchcz16k7v/public_html/wp-content/plugins/fusion-builder/shortcodes/fusion-table.php on line 119

TEXENE is the premier and recognized world leader in ungrounded static protective fabric for Type D (Antistatic) FIBC. As part of its on-going commitment to safety and product development, the company maintains a state of the art, full-scale FIBC safety performance testing facility in Miami Lakes, Florida, USA. This 12,000 ft3 environmentally controlled facility incorporates two laboratories, each one designed and equipped to meet the requirements of the international test standard, IEC 61340-4-4 Ed. 3.0. The laboratory is directed by Dr. Paul Holdstock, who possesses a PhD in electrostatics.

Inside the test facility, full-scale FIBC are filled and emptied under electrostatic charging conditions that simulate industrial environments. Testing parameters include FIBC grounded (for Type C bulk bags) or ungrounded (for Type D bulk bags), temperature, relative humidity and electrostatic charging rate. Performance measurements of the FIBC include charge transfer, surface potential, and incendivity testing using a gas probe with specific mixtures for a range of minimum ignition energies. In addition to bulk bag testing, the electrostatics laboratory is utilized to measure electrostatic properties, such as surface resistivity, breakdown voltage for fabrics, linear resistivity and resistance to groundable points.

To ensure the continued safety of ungrounded and groundable Type D FIBC manufactured from CROHMIQ fabric, Texene regularly conducts tests in its safety performance test laboratory under the Continuous Safety Certification™ Program.

Continuous Safety Certification (CSC) is a unique program provided by Texene to its customers and end-users. The CSC Program involves initial safety qualification of CROHMIQ static protective bulk bags to ensure each design meets the essential safety requirements of IEC 61340-4-4 for Type D FIBC. After initial safety qualification, random samples of production of CROHMIQ bulk bags are re-tested to ensure that they continue to provide the safety required by end-users.

The most important test that proves the safety of FIBC for use in flammable or explosive atmospheres is the incendivity, or ignition test. The principle is to fill the bulk bag under test with charged pellets and determine if there are any electrostatic discharges from the surface of the bulk bag with sufficient energy to ignite an approaching gas probe. The test parameters are selected to provide the severest challenge to antistatic FIBC so as to ensure they are able to perform safely under worst case conditions. The critical test parameters and the significance of each are described below.

Test Parameters & Their Significance

| Temperture & Humidity | The electrostatic properties of polymeric materials depend to a greater or lesser extent on the amount of moisture they are able to absorb from the atmosphere. There is too little moisture available at low relative humidity and so static charge tends to accumulate more readily and dissipate more slowly.

Some materials absorb a lot of moisture and at high relative humidity their resistance can be so low that spark discharges may occur if the materials are isolated from ground. To ensure that CROHMIQ Type D bulk bags are able to maintain safe charge dissipation without becoming too conductive, it is necessary to test at both low and high relative humidity. |

|---|---|

| Charging current | The rate at which charge flows into and out of a bulk bag depends on the speed of filling and emptying and the chargeability of the product. Charging current is the charge flow rate expressed as ampere (A), or more conveniently micro-ampere (µA).

End-user data has shown that sustained charging currents of about 3 µA are possible, with transients sometimes even higher. It is necessary to test using charging currents that replicate those found in industry. |

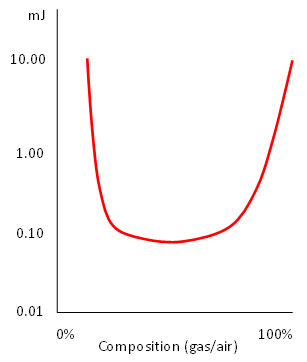

| Minimum Ignition Energy (MIE) | MIE is the smallest quantity of energy in an electrostatic discharge required to cause the ignition of a gas, vapor or powder. MIEs are normally expressed in milli-joule (mJ). The severest incendivity test is to use a gas mixture with the lowest practically relevant MIE.

Methanol vapor has the lowest MIE of any gas or solvent that is likely to be present when bulk bags are emptied. The MIE for methanol is 0.14 mJ. Click here for MIE of other common substances. |

| Gas Composition | The gas selected for incendivity testing is mixed with air to achieve the required MIE. The ratio of gas to air must be controlled to tight tolerances in order to maintain the specified MIE throughout the test. Furthermore, the composition of the air used must also be controlled.

MIE normally changes with gas composition in a way similar to that shown below:

Small changes in gas composition can produce a dramatic increase in MIE, making it easier to pass the test. Precise control of the gas composition is essential if the severity of the test is to be maintained. |

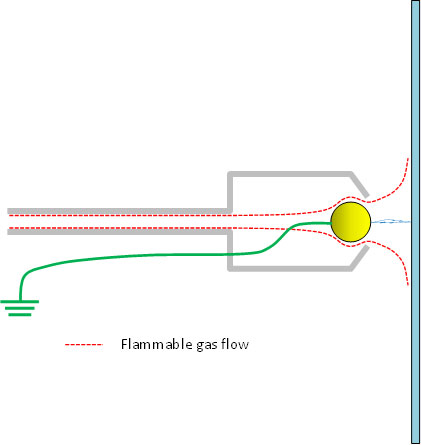

| Gas Flow Rate | The gas probe used for incendivity testing is a grounded metal electrode surrounded by a shroud that directs a flow of gas in front of the electrode, as shown below:

As gas exits the probe it is diluted by the surrounding air. It is necessary to minimize dilution because it changes the MIE of the gas. If the gas flow rate is high enough, dilution will not be significant. |

| Number of Repeat Tests | Ignition of a gas by electrostatic discharges is a probabilistic phenomenon. For example, a 1 mJ spark might ignite a 0.1 mJ MIE gas every time, but a 0.1 mJ spark may only ignite the same gas 1 time out of 100.

Confidence of a pass in incendivity testing (i.e. no ignitions) can only be achieved by performing a statistically significant number of gas probe approaches. Furthermore, approaches should be made at different locations on all sides of the bulk bag under test, during filling and emptying. |

Scroll or view in landscape mode to see full table.

Parameters used for Testing CROHMIQ® FIBC

| Temperature & Humidity | (23 ± 2) °C / (20 ± 5) %RH, and

(23 ± 2) °C / (60 ± 10) %RH |

|---|---|

| Charging Current | (3.0 ± 0.2) µA negative polarity |

| MIE | (0.14 ± 0.01) mJ |

| Flammable Gas | Ethylene |

| Air | (21.0 ± 0.5)% Oxygen, balance Nitrogen |

| Gas Composition | (5.4 ± 0.1)% Ethylene |

| Gas Flow Rate | (0.21 ± 0.04) litre/s |

| Gas Composition Monitoring | IR Ethylene Gas Analyzer providing constant, real-time monitoring |

| Calibration Checks | Before each test series:

|

| Number of Repeat Tests | At least 50 on each side, top and bottom (>200 per FIBC) |

Scroll or view in landscape mode to see full table.

Test Results

Breakdown Voltage

| Fabric | Reported Values | ||

|---|---|---|---|

| CROHMIQ blue™ | CROHMIQ white™ | ||

| 6.5 oz CROHMIQ Fabric | 3.1 ± 0.3 kV | 3.6 ± 0.2 kV | |

| 3 oz CROHMIQ Fabric | 2.9 ± 0.4 kV | 4.0 ± 0.4 kV | |

Scroll or view in landscape mode to see full table.

CROHMIQ fabric meets the requirements of Clause 7.2 of the International Standard IEC 61340 4-4 Ed. 3.0 (2018) because breakdown voltage is less than 6 kV.

Ignition Testings

| Parameter | Reported Values | |

|---|---|---|

| Atmosphere for conditioning & testing | 23 °C and 20 %RH 23 °C and 60 %RH |

|

| Flammable gas mixture | 5.4% ethylene, balance air (21% O2) at 0.21 litre/s | |

| Minimum ignition energy (MIE) | 0.14 mJ | |

| Filling rate | 1 kg/s | |

| Charging current | 3 μA (negative polarity) | |

| CROHMIQ blue™ | CROHMIQ white™ | |

| Total number of ignition attempts | 432 | 432 |

| Number of ignitions | Zero | Zero |

Scroll or view in landscape mode to see full table.

CROHMIQ FIBC meet the requirements of Clause 7.3.2 of the International Standard IEC 61340-4-4 Ed. 3.0 (2018) because no ignitions occurred.

CROHMIQ FIBC also meet the requirements for Type D FIBC as specified in: IEC/TS 60079-32-1: 2013, CLC/TR 50404: 2003, NFPA 77: 2019, NFPA 652:2019, NFPA 654:2017 and JNIOSH TR No. 42:2007.

TÜV SÜD Schweiz AG Process Safety (Test Reports 923533-17-0250-01 & -02)