Proving the safety of CROHMIQ FIBC

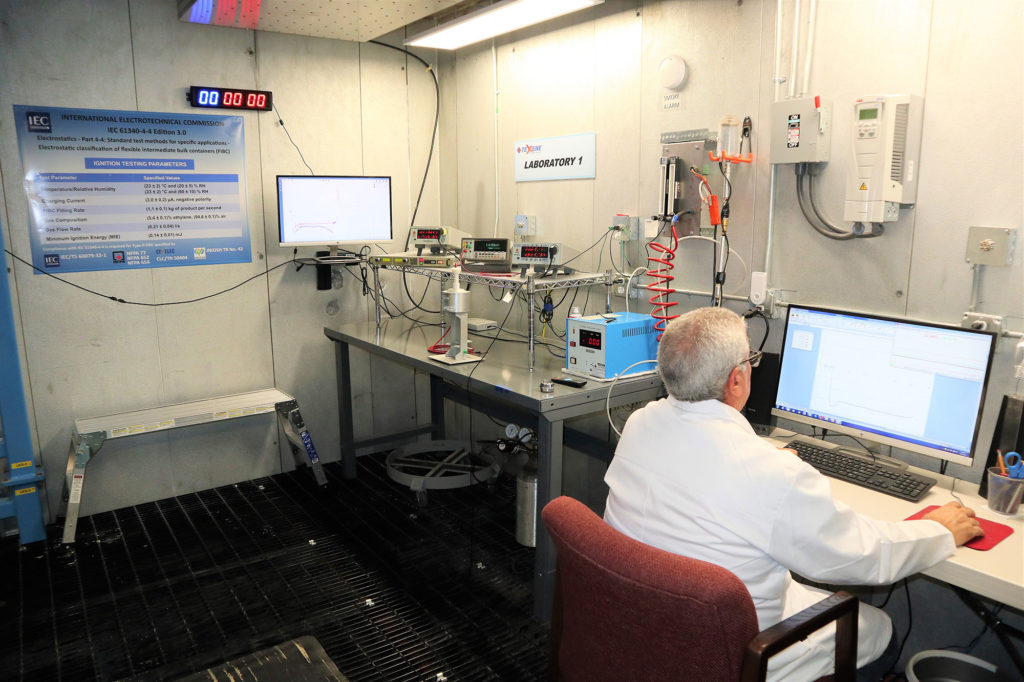

TEXENE is the premier and recognized world leader in ungrounded electrostatic protective fabric for Type D (Antistatic) FIBC. As part of its on-going commitment to safety and product development, the company maintains a state of the art, full-scale FIBC safety performance testing facility in Miami Lakes, Florida, USA. This 12,000 ft3 environmentally controlled facility incorporates two laboratories, each one designed and equipped to meet the requirements of the international test standard, IEC 61340-4-4 Ed 3.0. The laboratory is directed by Dr. Paul Holdstock, who possesses a PhD in electrostatics.

Inside the test facility, full-scale FIBC are filled and emptied under electrostatic charging conditions that simulate industrial environments. Testing parameters include FIBC ungrounded (for static protective Type D bulk bags) or grounded (for Type C bulk bags), temperature, relative humidity and electrostatic charging rate. Performance measurements of the FIBC include charge transfer, surface potential, and incendivity testing using a gas probe with specific mixtures for a range of minimum ignition energies. In addition to bulk bag testing, the electrostatics laboratory is utilized to measure electrostatic properties, such as surface resistivity, breakdown voltage for fabrics, linear resistivity and resistance to groundable points.

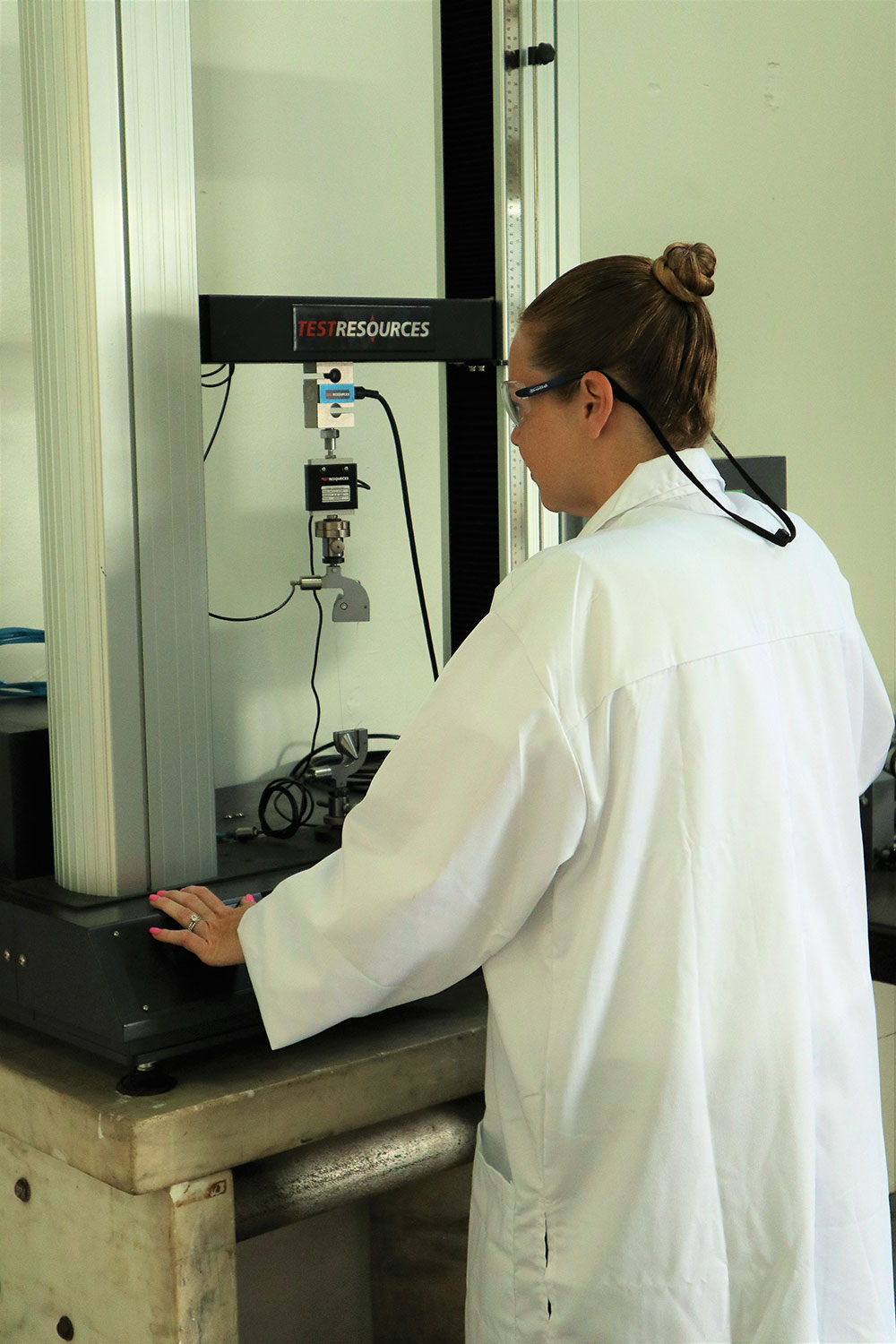

PHYSICAL TESTING

As well as providing the highest level of electrostatic safety, it is important that CROHMIQ fabrics provide the strength and durability required to withstand the rigours of industrial use. Physical testing of yarns, tapes and fabrics is carried out at Texene’s fabric production plant and at the physical testing facility in Miami Lakes. The range of testing includes:

- tensile testing of yarns, tapes and fabrics

- fabric weight

- coating adhesion

- durability to UV exposure

- durability to high temperature