Summary

- It is absolutely critical that Type C FIBC are securely and continuously grounded.

- An ungrounded Type C is by far the most dangerous type of FIBC.

- Type C FIBC have caused explosions because of grounding failures.

- Grounding failures occur because of obvious and not so obvious human error.

- Hidden grounding failures can occur because of manufacturing faults.

- Inter-lock systems can help to reduce human error, but they add cost and complexity to processes, and may not detect grounding failures caused by manufacturing faults.

- CROHMIQ Type D FIBC provide full static protection without the need for grounding.

- No special training, supervision or handling procedures are required when using CROHMIQ Type D FIBC.

- CROHMIQ Type D FIBC have a faultless safety record.

The safety advantages of CROHMIQ Type D FIBC are clear, and converting from Type C FIBC to CROHMIQ Type D FIBC is a logical, simple and safe choice.

The CROHMIQ® safety advantage

The main safety advantage of CROHMIQ Type D FIBC compared to Type C FIBC is the ability to provide full protection against the dangers of static electricity without the need for grounding.

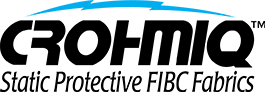

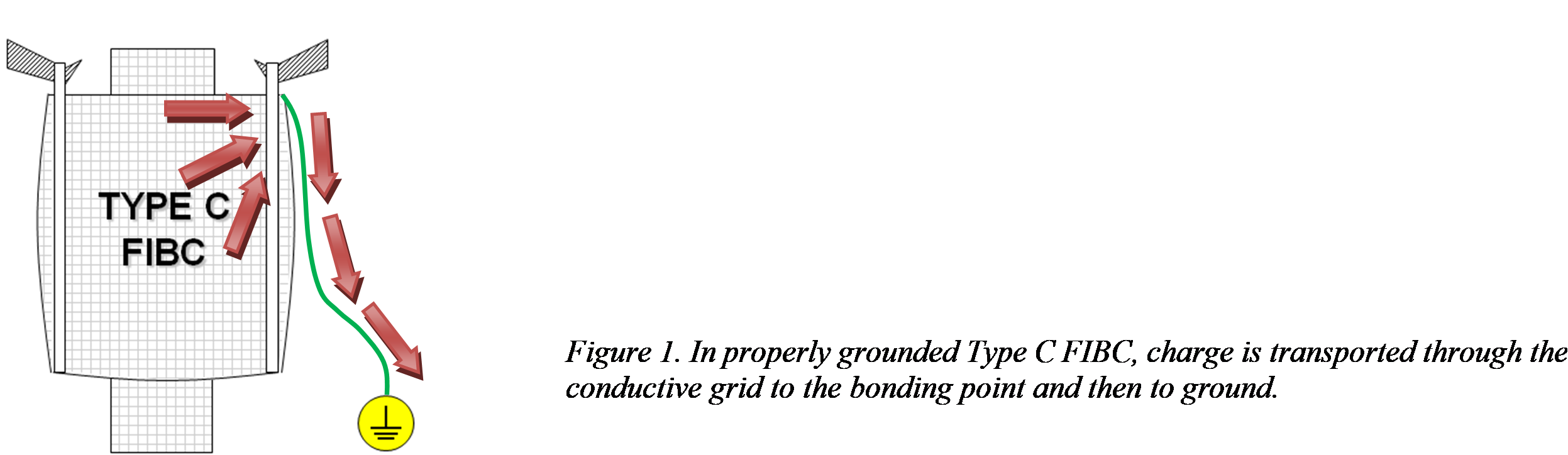

It is absolutely critical that Type C FIBC are securely and continuously grounded in order to prevent incendiary spark discharges. Figures 1 and 2 explain graphically the correct operation of Type C FIBC, and what can happen if the ground connection fails.

Explosions caused by Type C FIBC are not just theoretical. Dr L. G. Britton, in his paper in Process Safety Progress*, reported on a number of incidents involving Type C FIBC. The paper is reproduced, with permission, on the CROHMIQ website (link) and is useful in helping customers to understand the real and present dangers of using Type C FIBC. Without a secure ground connection, a Type C is by far the most dangerous type of FIBC.

Grounding failures

It is important to understand the different ways in which grounding can fail. Some are quite obvious: operators forgetting to attach ground cables, or ground cables becoming detached when bags are moved. Some failures are not so obvious and other examples of human error can occur. Operators can attach ground cables to wrong part of a bag, or attach a ground cable briefly, mistakenly thinking that once static electricity is discharged it will not build up again.

Using CROHMIQ Type D FIBC is a simple way to eliminate human error

It is necessary for all process operating employees to understand the need for grounding Type C FIBC and to be trained to do it properly. Supervisors are needed to check that proper grounding procedures are followed. Once companies understand the need for all this training, supervision and cross-checking, the option to eliminate it by using CROHMIQ Type D FIBC becomes a logical choice. CROHMIQ Type D FIBC provide the same electrostatic protection as Type C FIBC, but because they dissipate charge safely into the atmosphere, there is no need for grounding. And because they are always surrounded by the atmosphere, charge dissipation always occurs without the need for human intervention.

The use of inter-lock systems that prevent transfer of products into or out of FIBC unless a ground connection is in place is another way reduce the risk of grounding failure. These systems require two connections to be made at different points on the bag, a ground connection and a monitoring connection. The system measures the resistance between the monitoring point and ground and will only release locks to allow product to flow if the resistance is low enough, indicating the ground connection is present. Inter-lock systems add expense and complexity to FIBC handling operations. Companies will see the logic of avoiding the expense of inter-locks systems and keeping their processes simple and safe by using CROHMIQ Type D FIBC.

The hidden danger of Type C FIBC manufacturing faults

Inter-lock systems only detect a ground connection at one point on a bag. Therefore, they cannot detect manufacturing faults that can leave some panels electrically isolated from the rest of the bag. A common example of this occurs with spouts. Although spouts may be relatively small components, they are often subjected to high electrostatic charging currents, particularly when bags are emptied. A few simple calculations can demonstrate just how dangerous an ungrounded spout can be.

We can start by selecting some parameters. IEC 61340-4-4 specifies a charging current of 3 μA, which is considered to be worst case. For this exercise we can use what is perhaps a more typical charging current of 1 μA. IEC TS 60079-32-1 indicates a capacitance of 10 pF to 20 pF for small conductors, so it is not unreasonable to use 10 pF for the capacitance of the conductive grid in a spout. If the spout was completely isolated from ground, the resistance to ground would be greater than 10E14 Ω, but for this exercise let us assume that the spout is only partially isolated with a resistance to ground of 10E10 Ω. The parameters and calculations are:

Charging current I = 10E-06 A

Resistance to ground R = 10E10 Ω

Using Ohm’s Law, the voltage V = I × R = 10E-06 x 10E10 = 10E04 V

The energy stored on a capacitor E = 0.5 × C × V × V

The energy stored on the ungrounded spout with capacitance C = 10 pF = 10E-11 F is then calculated as E = 0.5 × 10E-11 × 10E04 × 10E04 = 0.5 × 10E-03 J = 0.5 mJ

If a spark occurs from the ungrounded spout, almost all of the energy stored on the spout will be released in the spark. Typical solvents (e.g. benzene, toluene, xylene) have MIE about 0.2 mJ to 0.3 mJ. Therefore, if a spark occurs from an ungrounded spout in the presence of such solvent vapours, there is more than enough energy released to cause ignition.

In accordance with the safety requirements of IEC 61340-4-4, CROHMIQ Type D FIBC are qualified for safe operation in explosive atmospheres with MIE as low as 0.14 mJ and when charging currents are as high as 3 μA.

Versatile safety

The industry demand that created the concept of Type D and resulted in the invention of CROHMIQ came from companies concerned for the safety of their customers. When a company packages its products in Type C FIBC, does it necessarily know that the facility that empties the bags, possibly in a process with flammable solvent, has the correct grounding systems and procedures in place? The answer very often is no. A company does not always know where or how its products will be used, but it still has product liability. And even if it does know that some of its customers can safely handle Type C FIBC, what can it do about the customers that cannot handle Type C FIBC? The solution in both cases is to use CROHMIQ Type D FIBC. As there are no special handling requirements and no need for costly and complex grounding systems, CROHMIQ Type D FIBC can be used safely in any facility. Users can rely on this versality to simply and streamline FIBC inventories by using CROHMIQ Type D FIBC for all their bulk packaging requirements.

Summary

- It is absolutely critical that Type C FIBC are securely and continuously grounded.

- An ungrounded Type C is by far the most dangerous type of FIBC.

- Type C FIBC have caused explosions because of grounding failures.

- Grounding failures occur because of obvious and not so obvious human error.

- Hidden grounding failures can occur because of manufacturing faults.

- Inter-lock systems can help to reduce human error, but they add cost and complexity to processes, and may not detect grounding failures caused by manufacturing faults.

- CROHMIQ Type D FIBC provide full static protection without the need for grounding.

- No special training, supervision or handling procedures are required when using CROHMIQ Type D FIBC.

- CROHMIQ Type D FIBC have a faultless safety record.

The safety advantages of CROHMIQ Type D FIBC are clear, and converting from Type C FIBC to CROHMIQ Type D FIBC is a logical, simple and safe choice.

*Process Safety Progress, Volume12, Issue 4, October 1993, Pages 240-250.