Terminology related to explosive atmospheres

What are explosive atmospheres?

explosive atmosphere

mixture with air, under atmospheric conditions, of flammable substances in the form of gas, vapour, or dust, which, after ignition, permits self-sustaining propagation (Source: IEC 60079-0)

explosive dust atmosphere

mixture with air, under atmospheric conditions, of flammable substances in the form of dust, which, after ignition, permits self-sustaining propagation (Source: IEC 60079-0)

explosive gas atmosphere

mixture with air, under atmospheric conditions, of flammable substances in the form of gas or vapour, which, after ignition, permits self-sustaining propagation (Source: IEC 60079-0)

Potentially explosive atmospheres exist in areas where there is a risk of explosion of mixtures of gas/air, vapour/air, dust/air or hybrid combinations of these mixtures.

In such hazardous areas there is a necessity to eliminate sources of ignition, such as sparks, hot surfaces or static electricity, which may ignite these mixtures.

The International Electrotechnical Commission (IEC) develops standards to support the IECEx Conformity Assessment Scheme, which provides a means for manufacturers, regulators and users of equipment used in hazardous areas to address the risk of fires or explosions from flammable gases or dusts. IEC standards are also used to support ATEX Regulations and Directives in the European Union (ATEX is derived from the French term ATmosphères EXplosibles), and national legislation in other countries around world.

In North America, the National Fire Protection Association (NFPA) develops similar standards to support national legislation.

Hazardous area classification

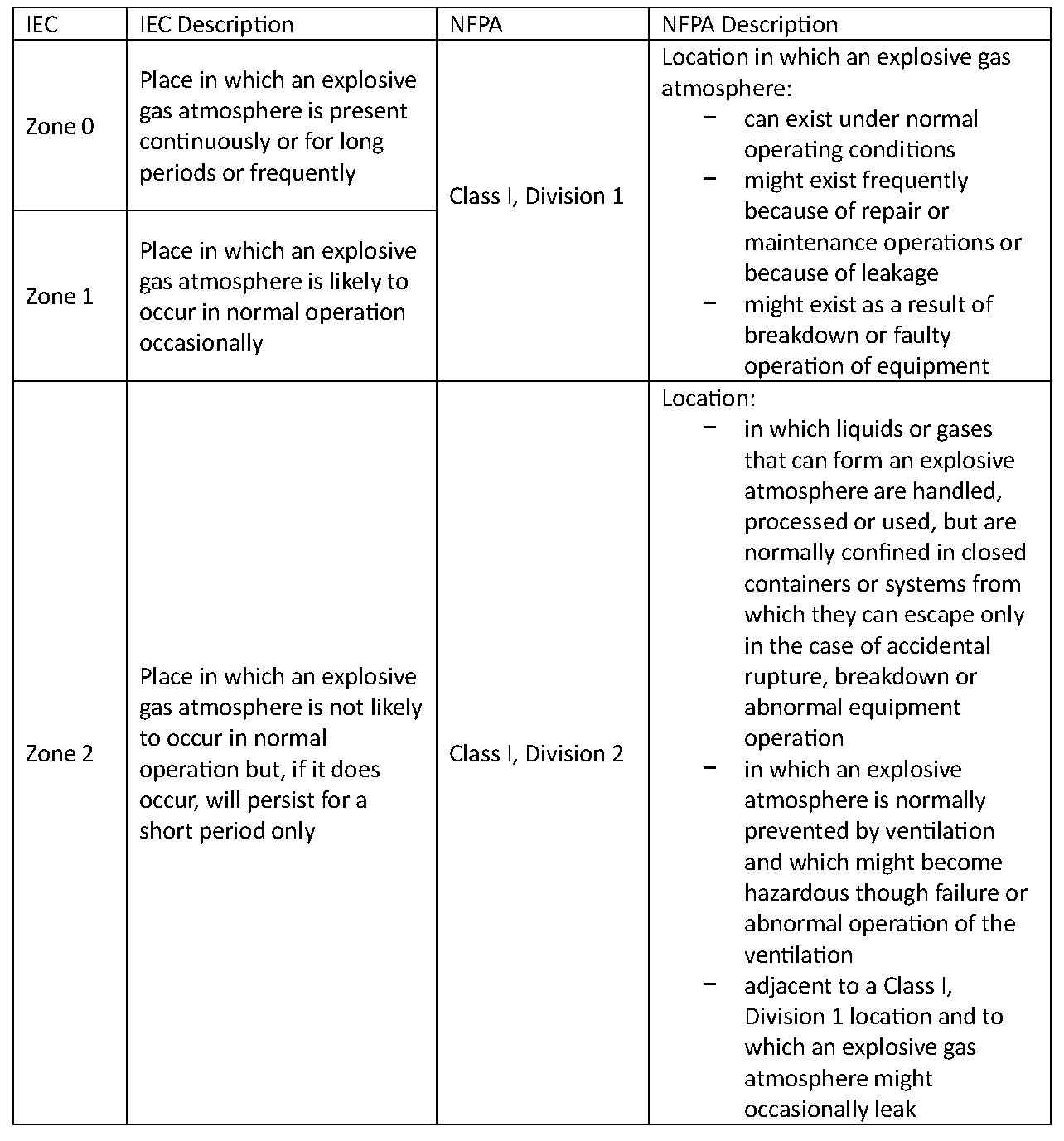

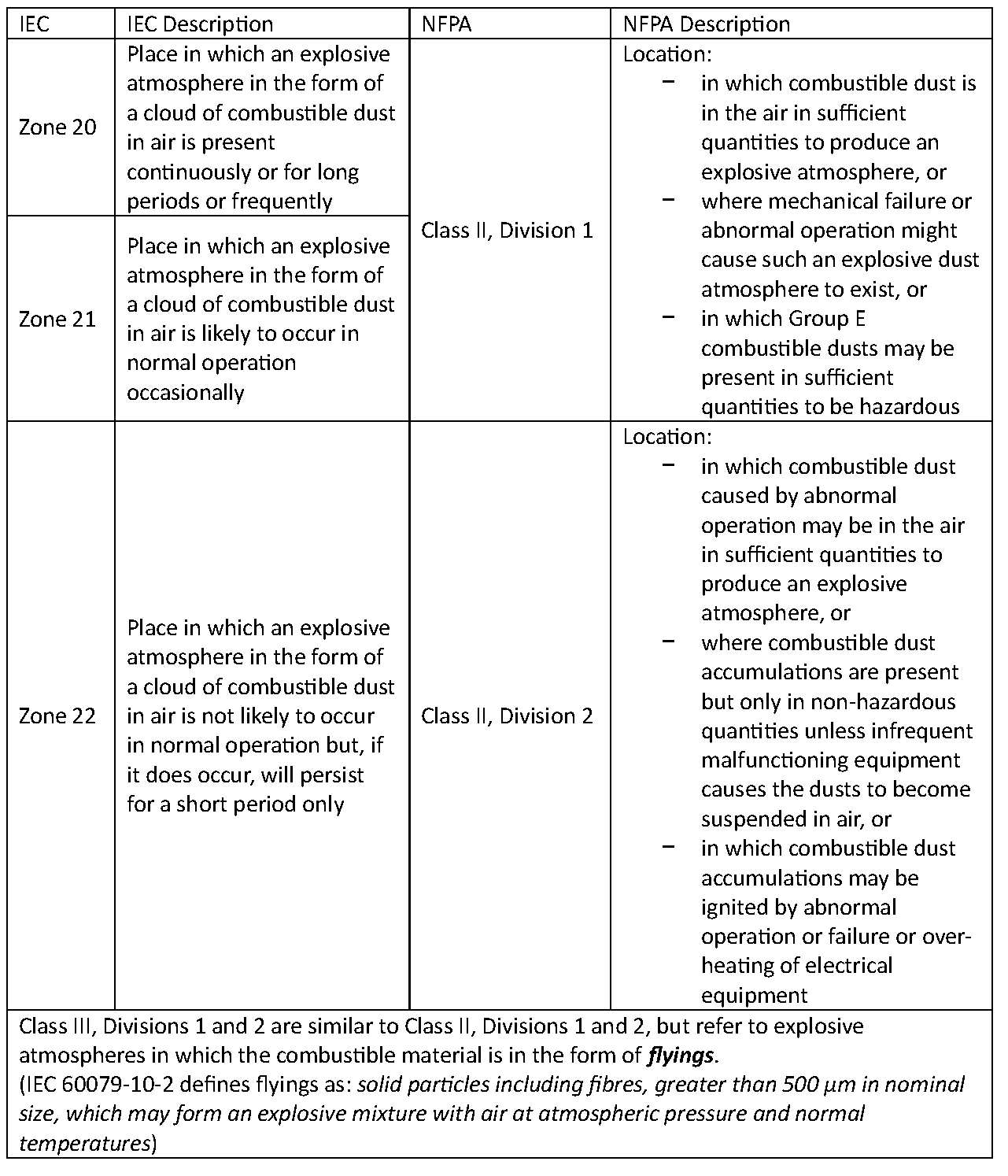

The probability of igniting an explosive atmosphere depends on a number of factors, including the nature of the explosive atmosphere and its sensitivity to ignition, and the likelihood of an explosive atmosphere being present. There are many different substances that can form explosive atmospheres, and many different scenarios that can result in the creation of an explosive atmosphere. To facilitate safe management of hazardous areas, the concept of hazardous area classification (HAC) is used to arrange the different types of explosive atmospheres and their likelihood of occurring into manageable groupings. The terminology used internationally (defined by IEC) and in North America (defined by NFPA) does differ, but the basic HAC concept is the same, and it is possible to transpose between the two systems.

In the IEC system, hazardous areas are divided into Zones. Hazardous areas containing explosive gas atmospheres are designated as zones followed by single digit: Zone 0, Zone 1 or Zone 2. Hazardous areas containing explosive dust atmospheres are designed as zones followed by two digits always starting with a “2”: Zone 20, Zone 21 or Zone 22.

In the NFPA system, hazardous areas are divided into Classes. Hazardous areas containing explosive gas atmospheres are designed as Class I and those containing explosive dust atmospheres are designated as Class II (note the Roman numerals).

Note: Since 2002, NFPA has provided for the option of using the Zone system as an alternative to the Class system. The NFPA Zones system closely follows the IEC system.

The likelihood of an explosive atmosphere occurring in a hazardous area is designated by the digits following the Zone in the IEC system, and by a Division number in the NFPA system. The descriptions for hazardous areas in IEC and NFPA are shown in the tables below.

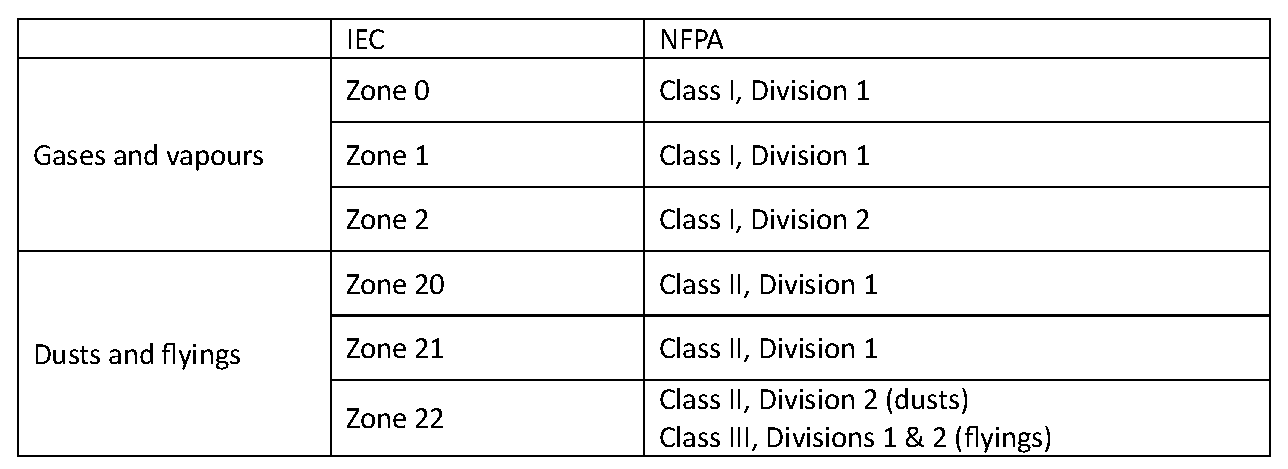

The table below shows an approximate transposition between the IEC and NFPA hazardous area classification systems.

Explosion groups

In order to make the very large number of flammable and combustible materials more manageable, both the IEC and NFPA hazardous area classification systems group materials together according to the ease of ignition. The terminology changes depending on whether reference is to an explosive atmosphere or to the equipment intended for use in the explosive atmosphere. The terms “explosion group”, “gas group” or “equipment group” may be used in different contexts, but they all relate to ease of ignition.

Two parameters are used to define the ease of ignition: maximum experimental safe gap (MESG) and minimum ignition current ratio (MIC Ratio).

MESG is defined as the maximum gap between two flat surfaces, under specified test conditions, that prevents an ignition of a flammable gas/air mixture propagating from an inner chamber through a 25 mm long path into a secondary (outer) chamber. The data generated from MESG testing is commonly used as a guideline in installing properly sized flame arresters on process equipment.

MIC Ratio is the ratio of the minimum current required from an inductive spark discharge to ignite the most easily ignitable mixture of a gas or vapor, divided by the minimum current required from an inductive spark discharge to ignite methane under the same test conditions.

IEC Terminology

Group I – firedamp gases found in coal mines

Group II – explosive gas atmospheres other than firedamp

Group IIA – MESG ≥ 0.9 mm (typical gas: propane; typical vapour: hexane)

Group IIB – 0.5 mm < MESG < 0.9 mm (typical gas: ethylene; typical vapour: diethyl ether)

Group IIC – MESG ≤ 0.5 mm (typical gas: hydrogen; typical vapour: carbon disulphide)

Group II gases may also be grouped according to MIC:

Group IIA – MIC Ratio > 0.8

Group IIB – 0.45 ≤ MIC Ration ≤ 0.8

Group IIC – MIC Ratio < 0.45

Group III – explosive dust atmospheres

Group IIIA – combustible flyings

Group IIIB – non-conductive dust

Group IIIC – conductive/metal dust

NFPA Terminology

Group A – acetylene

Group B – flammable gas or vapour: MESG ≤ 0.45 mm or MIC Ratio ≤ 0.4

Group C – flammable gas or vapour: 0.45 < MESG ≤ 0.75 mm or 0.4 < MIC Ratio ≤ 0.8

Group D – flammable gas or vapour: MESG > 0.75 mm MIC Ratio > 0.8

Group E – combustible metal dusts (excluding aluminium and magnesium and their alloys) and other conductive combustible dusts

Group F – combustible carbonaceous dusts (coal, etc.)

Group G – combustible dusts other than Group E or Group F (e.g. flour, wood, plastic, etc.)

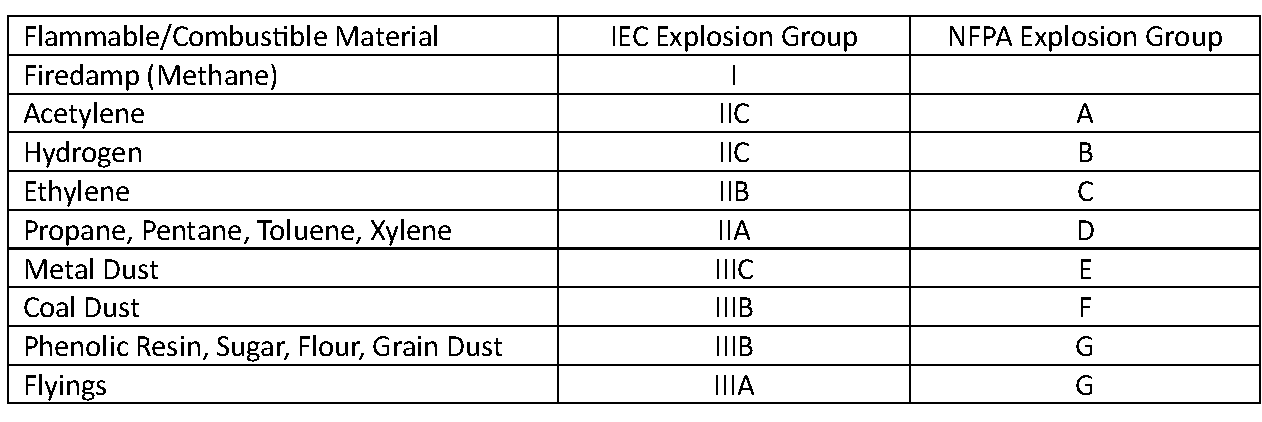

Some common flammable/combustible materials and their designated groups according to the IEC and NFPA systems are shown in the table below.

Selecting a safe FIBC to use in hazardous areas

The IEC and NFPA hazardous area classification systems can be used to select safe FIBC.

IEC TS 60079-32-1 and IEC 61340-4-4 both include a summary table matching the types of FIBC (Type A, Type B, Type C and Type D) to the hazardous area in which each type can be safely used. A copy of this summary table was included in the Type D FIBC Technology Monthly Newsletter for March 2024.

A similar table is provided in NPFA 77 based on the NFPA hazardous area classification system and a copy was also included in the Type D FIBC Technology Monthly Newsletter for March 2024.

An ignition parameter that is specific to electrostatic ignition risks is minimum ignition energy (MIE), which is the least amount of energy in an electrostatic spark required to ignite a dust, gas or vapour. MIE is used in IEC TS 60079-32-1, IEC 61340-4-4 and NFPA 77 to further refine the hazardous area classification system to distinguish between inert, combustible and flammable dusts, and to distinguish between gases within the same Explosion Group.