United States of America

The US Government agency responsible for enforcing health and safety legislation is the Occupational Safety & Health Administration (OSHA), which is part of the US Department of Labor. OSHA develops and publishes regulations and standards promulgated under the Occupational Safety and Health Act of 1970 (OSH Act) (29 USC § 668).

OSHA makes reference in its standards and guidelines to other national consensus standards, including those published by the National Fire Protection Association (NFPA).

If an accident occurs, OSHA may prosecute companies that have not followed its standards and other national consensus standards and recommendations, including those published by NFPA.

NFPA has an extensive library of standards and recommended practices. NFPA 77 is the Recommended Practice on Static Electricity, and is referenced in OSHA standards for process safety management.

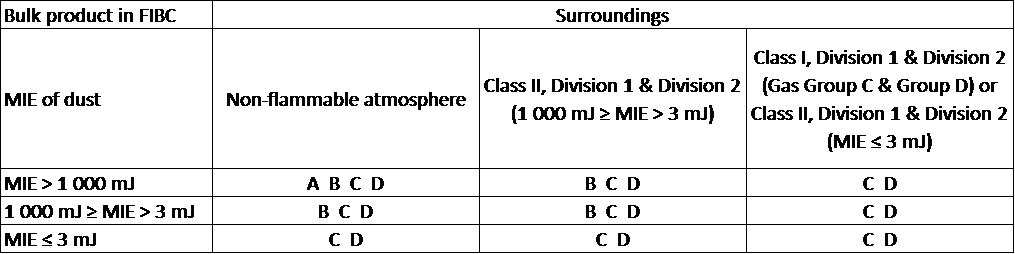

The first edition of NFPA 77 was published in 1966 as an amendment to the earlier Manual on Static Electricity (NFPA 77M). NFPA 77 has been revised several times, 2024 being the current edition. Beginning with the 2014 edition, NFPA 77 has used the classification system for FIBC specified in the International Standard IEC 61340-4-4, and provides recommendations for the safe use and use restrictions for the four types: Type A, Type B, Type C and Type D. In the 2024 edition of NFPA 77, Table 16.6.3 provides a summary of the recommended use of different types of FIBC, which is essentially the same as that published in Table 19 in IEC TS 60079-32-1: 2013, and Table 5 in IEC 61340-4-4: 2018.

NFPA 77: 2024 Table 16.3.3 – Use of different types of FIBCs

Note: MIE = minimum ignition energy. An explanation of the nomenclature used for hazardous areas and gas/dust groups will be provided in a later newsletter.

Table 16.3.3 summaries the recommended use of FIBC. There is also text in NFPA 77: 2024 recommending restrictions on use:

- Types A, Type B and Type D FIBC should not be used for conductive powders, i.e. powders with low resistivity (§ 16.6.4.2 (3), 16.6.5.4 (4) and 16.6.7.3);

- Type A FIBC should not be used for powders or granular materials that have MIE of 1000 mJ or less (§ 16.6.4.2 (1));

- Type A and Type B FIBC should never be used in areas where a flammable gas or vapor is present (§ 16.6.4.2 (2) and 16.6.5.4 (3)).

Europe

In the European Union (EU), the main legislative framework for process safety management to prevent ignition of explosive atmospheres is defined and specified in the ATEX Directives. “ATEX” is derived from the French term ATmosphères EXplosibles, meaning explosive atmospheres. Explosive atmospheres can be formed by combustible or flammable powders or dusts from granular materials, or by flammable gases or solvent vapours. There are two ATEX Directives: Directive 99/92/EC (also known as ATEX 137 or the ATEX Workplace Directive) and Directive 2014/34/EU (also known as ATEX 114 or the ATEX Equipment Directive). EU Directives are obligatory publications of Acts of the European Parliament and Council, and all EU Member States are obliged to implement Directives in their own national laws. For example, in Great Britain the requirements of the ATEX Workplace Directive are put into legal effect in the Dangerous Substances and Explosive Atmospheres Regulations 2002 (DSEAR), and the requirements of the ATEX Equipment Directive are put into legal effect in the Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres Regulations 1996. Both of these regulations survive in British Law post-BREXIT.

ATEX Directives are supported by European Standards, which are CEN and CENELEC implementations of ISO and IEC Standards. EU Member States are obliged to implement CEN and CENELEC standards as their own national standards. For example, IEC 60079-0 is implemented by CENELEC as EN IEC 60079-0, and by BSI as BS EN IEC 60079-0. There can be additional administrative and editorial text in each implementation, but the technical requirements and recommendations are identical. In many countries, standards remain voluntary, but in others, such a Germany, technical requirements of standards are implemented in a more regulatory manner. For example, some of the technical requirements from IEC 60079-0 are incorporated into the German Technical Regulations for Hazardous Substances TRGS-727.

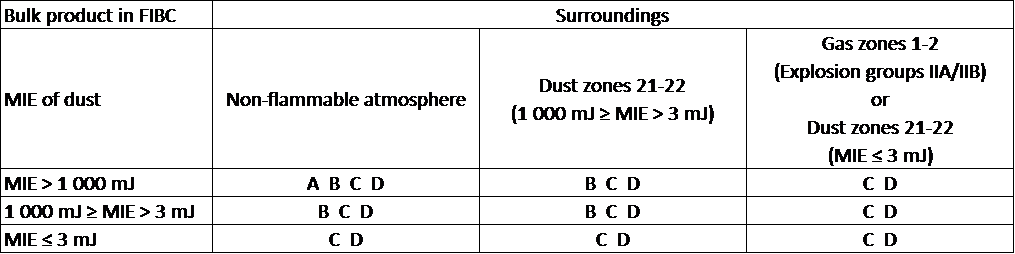

The two main standards relating to the use of FIBC in hazardous areas containing explosive atmospheres are IEC TS 60079-32-1, which specifies the general requirements for all operations in hazardous areas, and IEC 61340-4-4, which specifies the requirements for FIBC. Both of these standards provide a summary table specifying the use of the different types of FIBC in different hazardous areas.

IEC TS 60079-32-1: 2013 Table 19 – Use of the different types of FIBC

IEC 61340-4-4: 2018 Table 5 – Use of different types of FIBC

The IEC nomenclature for the hazardous areas and gas/dust groups is different from the NFPA nomenclature because of the different systems used in USA and internationally. Nevertheless, the technical recommendations of the summary tables are identical.

Whether voluntary or mandatory, standards provide companies with a recognised way to demonstrate compliance with legal requirements of ATEX Directives. Failure to comply with standards can result in legal prosecutions if accidents occur. The UK government regulator, the Health & Safety Executive (HSE), cited non-compliance with PD CLC/TR 60079-32-1 (the BSI implementation of IEC TS 60079-32-1) in its incident report following an explosion at a paint factory in 2020 involving the use of the wrong type of FIBC. In the prosecution that resulted, the company was fined £800,000.