CROHMIQ® Static Protective Type D FIBC Fabrics are made from at least 95% polypropylene and are compatible with most common recycling processes. CROHMIQ bulk bags have been recycled at the end of use life for many years to produce recycled polypropylene (RPP). The resulting post-industrial RPP can be used in the manufacturing of many different products through moulding and thick sheet extrusion processes. Thanks to its durability, strength, and low weight, RPP is utilized, for example, in furniture, luggage, toys, buckets, tubs, crates and automotive parts.

Plastic identification symbols

To help end-users identify the type of plastic that products are made from, a series of symbols have been standardised. Each symbol shows a triangle of “chasing arrows” around a number code, with an acronym below the triangle. The number code and acronym indicate the type of plastic used to make the product. The number code for polypropylene is 5 and the acronym is PP. The symbol can be included on manufacturer’s labels on FIBC to show what they are made of, and to remind end-users that the bags can be recycled.

At present, there are no regulations that specify the minimum content of mono-material in a plastic product in order to use one of the identification symbols. Nevertheless, for recycling purposes, a plastic is considered a mono-material if the content of other material is less than 5%. In CROHMIQ fabrics, the other materials, which makes up less than 5% by weight, are those typically found in FIBC fabrics – pigments, processing aids, UV stabilisers and some polyethylene in the coatings. None of these ingredients preclude CROHMIQ fabrics from being recycled as polypropylene, but when considering bulks bags as a whole, there are some additional considerations.

FIBC design considerations

Attachments

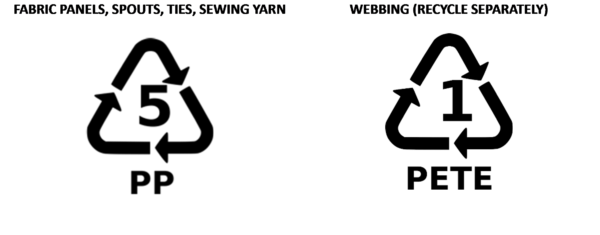

If FIBC are to be recycled without first removing attachments such as webbing, ties, labels, etc., the materials used for attachments need to be considered. Ideally, all attachments should be made from polypropylene. That way, the 5-PP symbol can be included on the manufacturer’s label on bags to indicate to end-users that the whole bag can be recycled as polypropylene.

Polyester, as may be used for webbing, can be problematic for recycling. If significant quantities of polyester are mixed in with polypropylene, the quality of the resultant RPP is degraded and may not even be suitable for moulding applications. FIBC with polyester webbing can still be recycled, but it may be necessary to remove webbing first and recycle the webbing separately. Plastic identification symbols can be used to provide helpful information to end-users, as shown in the example below.

Pigments and printing

Pigments and printing ink by their very nature are designed to produce bold colors. The presence of even tiny quantities in reclaimed materials will result in obvious coloring of RPP. For moulding and thick sheet extrusion applications, this is not usually a problem because many of the products produced by these processes can be re-colored as required. If RPP is to be used to make FIBC fabrics, the muddy grey color that is typical of post-industrial RPP is more problematic. Bulk bags are traditionally white, or in the case of CROHMIQblue™, a distinctive trade-marked pale shade of blue.

FIBC designed for recycling back into FIBC should minimise the use of pigments in fabric and webbing. End-users should be encouraged to use placards and labels that can be easily removed before recycling rather than rely on large areas of printing on the sides of bags.

Contamination and residue

There can be several pounds of residual product left inside FIBC. Some of these residues are fairly inert and will not adversely affect the quality of RPP. Others are more active and must be prevented from entering the final stages of recycling. The first stages of recycling include washing chopped reclaimed materials and this will remove most residue and contamination. However, there are chemicals that are not easily washed away and these must be prevented from entering the recycling process by careful and thorough screening to quarantine any FIBC that have previously contained harmful or undesirable products.